The future of hydrogen-powered vehicles is bright. But the high cost of refueling equipment nearly doubles the cost of hydrogen at the pump. By designing a transformative hydrogen refueling station, researchers at the U.S. Department of Energy’s (DOE) Argonne National laboratory are helping to lower the cost and increase the efficiency of pumping hydrogen at refueling stations.

Hydrogen fuel cell vehicles are operating in a few states — primarily California. Hydrogen stations consist of a compression and storage system, precooling unit, and a nozzle that connects with the fuel cell vehicle, much like a regular gas station. But the high cost of refueling stations is hindering widespread adoption.

In developing the patented refueling technology, Argonne scientists Amgad Elgowainy and Krishna Reddi targeted one of the costliest components: the compressor. Hydrogen is typically stored in large tanks at fueling stations as a buffer to aid the compressor during vehicle fueling.

Despite the high price tag, compressors are typically operating well below their full potential. Designed for peak demand, the oversized compressors were often idle during off-peak hours, impacting the cost of hydrogen fuel.

The Argonne technology consolidates the pressure of the hydrogen in the supply storage vessels during idle periods (i.e., when dispensers are unoccupied). When the dispenser is activated for vehicle fueling, the compressor receives a high-pressure stream of hydrogen, enabling a high fueling rate during peak fueling demand.

Elgowainy and Reddi expect the design to save refueling station operators up to 30% on their equipment costs by minimizing the compressor’s down time.

“Argonne is a global leader in hydrogen fueling modeling and analysis, and the laboratory’s hydrogen delivery and fueling models are used by thousands in over 25 countries,” says Elgowainy.

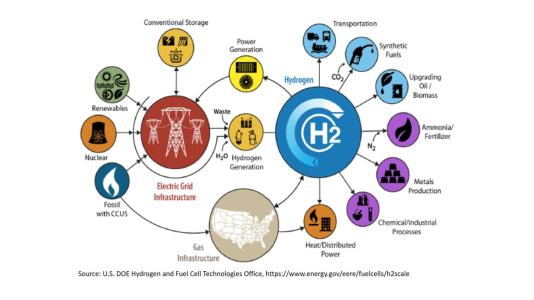

Argonne was granted three patents for its pressure consolidation methods. Argonne has transferred the technology to PDC Machines, Inc. (PDC), a U.S.-based global compressor manufacturer, through the DOE’s Hydrogen at Scale (H2@Scale) initiative, and a technology licensing agreement between Argonne and PDC.

The potentially disruptive technology has been demonstrated at laboratory scale and is ready to be deployed commercially, says Elgowainy. The Federal Laboratory Consortium (FLC) bestowed its Excellence in Technology Transfer award on the patented hydrogen refueling technology in 2019.

This article is part of Argonne’s ongoing “Hydrogen Highlights” series.